Have you been caught with an unexpected inventory stock-out this month? Do you have a feeling it could happen again next month, too?

Life would be so simple if you only sold one or two products. Even better if you were fortunate enough to have many independent customers who's individual order fluctuations had no real impact on your monthly sales. And while we're dreaming, how about short lead times for the components you require? For too many of us, this simply isn't the case. I've known companies that believe that four weeks from today is long term planning (it isn't, by the way). I've worked with folks who insist that their products defy forecasting (actually, they can be forecast). They try to place vendor purchase orders when someone notices the inventory is getting low. And I've seen companies actually try to operate projecting their inventory requirements only one time per month. It's just crazy. And whether you're a distributor or a manufacturer, stock outs are incredibly expensive in terms of customer satisfaction not to mention the cost of premium freight. A practical way to implement MRP... Bucket Manager is reasonably priced and will work with your existing software. You won't need to replace any existing systems you currently use in order to use Bucket Manager to generate your planning.

Nine Symptoms that you really need Bucket Manager...

- Too often, you are often surprised to run out of stock or find yourself unable to fill an unexpected large order.

- You are spending money on premium freight.

- You struggle to determine the projected inventory for any component or finished goods item at specific dates in the future.

- You are unsure of the exact date long lead time purchases should arrive.

- Keeping appropriate inventory on hand without running out is a priority for you.

- You purchase items with long lead times.

- You purchase parts and have multiple open purchase orders for a part at any time, making it difficult to determine exactly what your inventory will be at some future date.

- You struggle to determine whether you really can accept a large, unexpected order without jeopardizing your existing customers.

- You schedule large lot runs of multiple parts and need to know ahead of time if your schedule meets all customer orders on time.

- You not only sell finished products, you sell components or replacement parts, too. You find it difficult to know for certain when you might need to replenish these component supplies.

My Real World experience...

All I really wanted was a crystal ball. I just wanted to know about problems ahead of time, while there was still time to do something! I needed tools to streamline my forecasting and determine what production and purchase orders needed to be placed, which ones needed to be expedited and which could be pushed out.

This really is possible. I've implemented these systems and have seen actual line fills go from 60% to 99% and above, while customer order lead times were reduced from 2 weeks to zero. At the same time, inventory was reduced 45% freeing up lots of additional manufacturing space while over-all sales rose by one third. Expedited freight charges dissappeared and wow, were the customers pleased!

You can do this, too. It does take some effort and it does require the proper tools and honestly, it will take some time and commitment. But the results can be phenomenal.

Agenda Development's Bucket Manager works with your existing accounting-oriented software and streamlines the forecasting/planning for you.

Bucket Manager will:

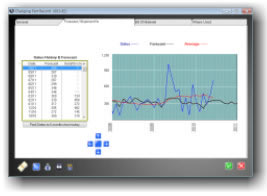

- Consider your planned sales, actual customer orders in-hand, starting inventories, desired safety stock levels and planned vendor receipts to project inventories out months into the future. If you are a manufacturer, it will use your bill of materials information to show you exactly when you will need each and every component. You can tell at a glance which parts need to be ordered, expedited or delayed.

- Make forecasting a breeze by graphing monthly sales history, testing multiple forecasting tools and suggesting the right model to use for each individual product. If your business is seasonal, your specific seasonality can be applied to your forecast instantly.

- Eliminate stock outs especially on long lead time items by showing you when you are heading into trouble. Sometimes months ahead of time! And it will do this for every component too if you manufacture products.

- Apply your company's particular seasonality curve to project future sales.

- Projects weekly inventory positions many months in advance.

- Recommends which purchase orders to place, which to expedite and which to delay.

- Creates a unique Crash & Burn report that shows a hot list of required products sorted by date priority.

- Integrates with Work Center Manager which handles short term planning, Kanban scheduling and just in time production.

What is required to implement MRP?

To run an MRP system, you will need the following things in place:

- Unique part numbers assigned to your finished goods and components.

- A system that maintains your current inventory, customer orders and your purchase orders issued to vendors.

- If you are a manufacturer, a bill of materials that defines what components are used to build each finished good item.

- Historical sales data. While not necessary, importing your sales history will enable you to use Bucket Manager's visual forecasting tool on day one.

What will I need to do?

How much time is required?

We like to re-plan daily. It only takes minutes. Typically, reviewing forecasts can be done once a month. You may choose to re-plan more or less often depending on how dynamic your business is. To run the re-planning procedures you will do the following:

- Export the current inventories into a CSV (ascii) file.

- Export your current open vendor purchase orders (PO's).

- Export your customer orders from your current system.

Then generate the MRP. The time required depends upon the number of parts in your database, the complexity of your product, the speed of your PC and the speed of your network. But the speed will astound you. (A real life example: 2,200+ inventory items, 750 active selling parts, modest network and a dated PC can regenerate the entire MRP planning system in 5 minutes.)

Is MRP difficult to run and maintain?

With proper software, it is not difficult but it does require some discipline.

Once you have the basics in place, generating the MRP is very simple and is so fast, you can re-plan your system in a few minutes each day. A typical system with about a thousand parts, forecasted out 6 months into the future can easily regenerate in as little as 10 minutes. It can easily be done daily, giving you a heads up warning based on current customer orders. You will wonder how you survived without this type of system.

But you will need to maintain accurate inventories and, if you are a manufacturer, you will need to maintain an up to date bill of materials.

We recommend reviewing your forecast monthly. The tools included with Bucket Manager make this a breeze.

We can help you implement MRP with phone or on-site consultation if you need it. Interested? Find out more.Give us a call or email us.

|

![]()

![]()

Week by week inventory projections clearly show ending inventories, vendor lead times and critical situiations.

Week by week inventory projections clearly show ending inventories, vendor lead times and critical situiations.